air compressor working principle in tamil

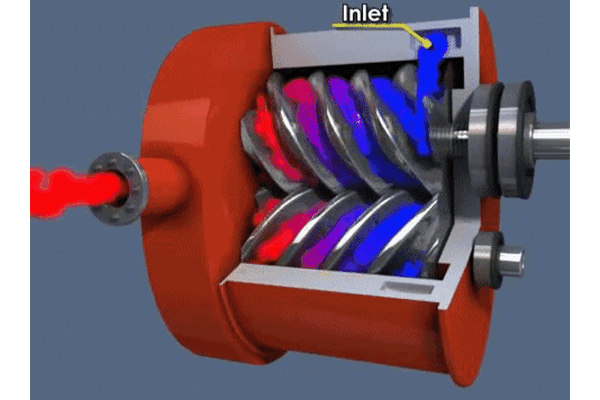

An air compressor is a pneumatic device that converts power into potential energy stored in pressurized air. Rotary Screw Air Compressors.

Compressor Maintenance Training Working Animation Gas Air Compressor Air Compressor Gas Compressor

Piston allows the atmospheric air to enter into the cylinder.

. Both the scrolls are separated by a small gap enough for a thin film of oil. Air compressors work by forcing atmospheric air under pressure to create potential energy that can be stored in a tank for later use. The compressed air can be used as energy as its released.

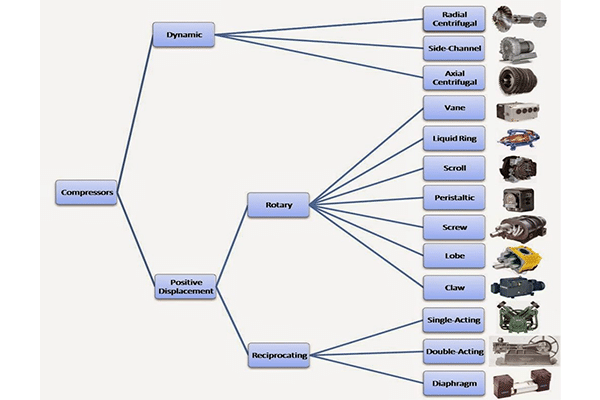

Think of it like an open balloon. Compressors Types and Principle of Working A compressor is a device or equipment which compresses the fluid from a low pressure to a high pressure. The oil film acts as a seal to prevent air from escaping between the low pressure and high pressure chambers.

A crankshaft moves a piston through a connecting rod in a linear fashion along the length of a cylinder in which it fits snugly. By one of several methods an air compressor forces more and more air into a storage tank increasing the pressure. The initial volume when the piston is at top is zero Assuming there is no bumping clearance.

When the tanks pressure reaches its engineered upper limit the air compressor shuts off. Since we know that air is compressible and we only need some mechanical device to do that and for that we have air compressor. Thus as the piston moves from top to bottom a volume of air V1 is drawn into the compressor.

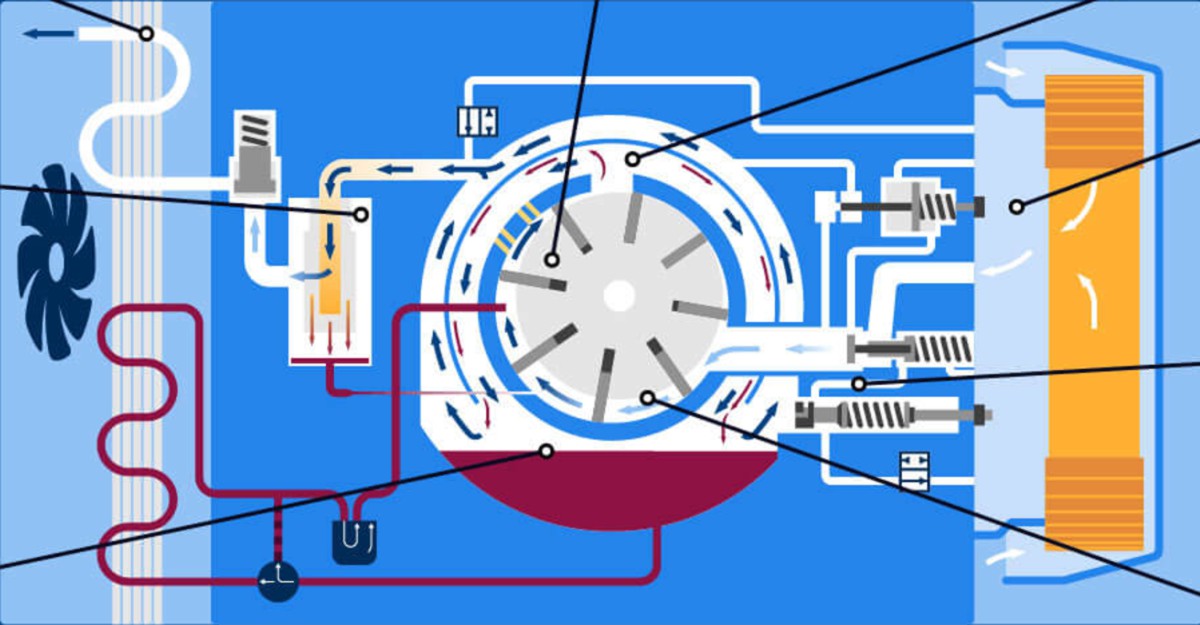

The core of how air compressors work is boiled down to two methods of air displacement. Air compressors work by forcing air into a container and pressurizing it. In order to compress air the internal components of a compressor must move or change position to mechanically force the air through the chamber where it is compressed and stored until use.

In this video we can know about the working principle of an air compressor used in shipthis is a two stage compressor. Piston air compressors pump is operated by a piston and connecting rod with a cylinder a valve-head and a crankshaft. The principle of an air compressors functioning is like that of an internal combustion unit.

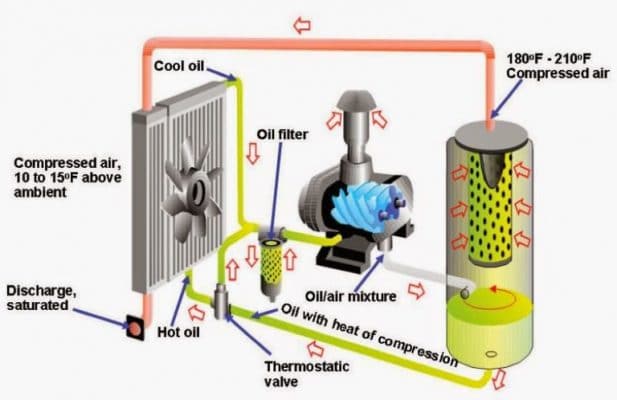

Master cylinder wheel cylinder oil reservoir. Positive Displacement is the method that most compressors use. Here I will share the information on screw air compressor with you because every engineering plant requires compressed air to perform various operations.

Since the instrument air compressor didnt constantly supply a certain flow thus it needs some control scheme in order to operate the instrument air compressor efficiently. It takes air form one end and than squeeze this air to high pressure and deliver it to the other end for various application. Compressed air is used as a working substance.

Due to its troublefree operation this type of compressor is most popular in the industry. The temperature of air is T1. Air enters the compression chamber.

If youre in an industry that demands air purity at 100 clean levels then a compressor that doesnt rely on internal oil is a top bet. Since energy is required to compress the air energy is released as the air expands and returns to atmospheric pressure. Product DescriptionWe have been manufacturing a wide range of compressor piston ring pressure ring wearing ring which is customized as per the specifications of our clients.

The compressed air then is held in the tank until called into. An air compressor as the name indicates is a machine to compresses the air and raises its pressureThe air compressor absorbs air from the atmosphere and compresses it. The fundamentals of how oil-less air compressors do their work means you could be looking at lower costs a better footprint and cleaner air.

The compression of air is done by first drawing a volume of air into its cylinder through suction valves during suction stroke by the piston then compressing discharging it on the return stroke of the piston through delivery valves. The following explains the working principle of the Pneumatic Reciprocating Compressor which progressively converts power into potential energy with the help of power or oil engine. As the piston moves up the air is compressed polytropically PVn C.

As the rotors turn the compartment becomes progressively smaller thereby compressing the entrapped air. This article gives a description on compressors working and the various types available. To avoid various faults occurs during.

There are on-off or startstop control loadunload control and also variable speed control. This is a method in which the air is forced into a chamber where its volume is reduced to raise the pressure. Then the air is forced through an opening in the tank where pressure builds up.

Air is drawn in through an open valve as the piston moves upwards providing ample space for a high volume of air. The working principles can be explained in two broad terms. From the storage vessel it can be carried by pipeline to a location where a supply of compressed air is needed.

As a result the vertical protector angle actions function efficiently in. This simple working is used in every Reciprocating Air Compressor. Air gets sucked into the cylinder through the cylinders top inlet valve and the second valve discharge the compressed air.

Just like an open balloon the pressure builds up when the compressed air is deliberately released converting the potential energy into usable kinetic energy. Screw Compressor is the precision technology machine to get compressed air. Compressed air leaves through the outlet port.

Hydraulic oil is used as a working substance. These compressor piston rings possess rich features of high strength pressure resistance and high strength. Air compressors were designed to compress air to higher.

The Scroll Compressor is made up only 2 primary components. When air is compressed it is under pressure greater than that of the normal atmospheric pressure and it characteristically attempts to return to its normal state. The common air compressors that follow this working principle are.

Theyre powered by an engine that turns electrical energy into kinetic energy. It also gives insight on selection of compressors and ways of capacity Variations. Air compressor unloader valve brake valve brake chamber.

Air brake has more powerful than a hydraulic brake. Hydraulic brake has less powerful than air brake. Then it sends to a storage vessel under high pressure.

The ends of the rotors uncover the inlet. The air is entrapped in the compartment formed by a male lobe and a female flute. The orbiting scroll traps air in each of the chambers during rotation and.

Top 10 Air Compressor Manufacturers In Coimbatore

Compressed Air Basics Rotary Screw Air Compressor Works

Air Compressor Basics Compressor Types Youtube

What Is The Working Principle Of A Reciprocating Air Compressor Answer Request Quora

Compressor Basics Reciprocating Air Compressor Works Inc

Reciprocating Compressors Reciprocating Compressor Reciprocating Air Compressor Compressors

Compressed Air Basics Rotary Screw Air Compressor Works

The Workings Of An Air Compressor Highways Today

Define Air Compressor And List Its Application M4 01 Te In Tamil Youtube

Screw Air Compressor Working Principle Youtube

Working Principle Of Air Compressor In Tamil Youtube

How Does An Air Compressor Work Compressor Types Tutorial Pneumatics Youtube

Air Conditioning Compressor Types Ac Compressors

Compressor Basics Types Of Compressors Air Compressor Works Inc

The Workings Of An Air Compressor Highways Today

What Is Positive Displacement Air Compressor Air Compressor Compressors Compressor